More about Bf 109G-10 manufactured by Erla and WNF.

The Bf 109G-10 was not a result of standard development of the fighter, but rather a result of urgent demand for the highest number of powerful fighter aircraft possible. In mid-1944, the DB 605D engine was completed after a prolonged development, an anticipated unit for the Bf 109K. As development of the new model suffered from constant delays. it became obvious in early summer 1944 that Bf 109K serial production would not begin in any foreseeable future. Moreover the Bf 109K featured numerous changes as compared to earlier models and thus problems and delays could be expected when launching serial production. As the pressure to manufcature and deliver higher number of aircraft was strong, any fall in production was not acceptable. On the other hand there was a possibility to install the advanced DB 605D engine in the existing Bf 109G airframe (currently the Bf 109G-6 with the MW 50, later designated as G-14) and thus avoid possible complications. This was to present no significant problems as far as the design was concerned, as earlier DB 605A and AS and the new DB 605D differed very little in size and their attachment points were identical. Mating together the existing Bf 109G framework and the new engine would remarkably increase operational performance at all altitudes while maintaining the on-running mass production.

The aforementioned reasons,i.e.,delays in Bf 109K development and easy switch to production of a DB 605D-powered Bf 109 gave rise at the turn of June and July 1944 to a new Bf 109G model powered by the advanced engine. It was designated the Bf 109G-10. Erla Leipzig was assigned to develop the design as the Regensburg branch was fully preoccupied with work on the Me 262 and with designing the Bf 109K. A note in an official list of Bf109 models of 2nd August 1944 documents the fact, as it described the Bf109G-10 as "Bastard Flugzeug der Fertigung Erla". The new model was to be developed by Erla as an independent design,not connected with the on-going development of Bf109G and K. Reports of the Bf109G and K program (run by Regensburg) therefore did not mention the G-10 model.

Erla Leipzig solved problems of the DB 605D installation easily,partly because there were not many. The Bf 109G-14 framework (i.e. the G-6 with the MW 50 system) was used as the base and the design probably drew on experience with the DB 605AS installation in the Bf 109G-10 in early 1944. Changes in internal structure of the aircraft were not necessary; attention therefore focused on the engine. The DB 605D required more space in the lower part than the DB 605AS due to larger covers being required for the camshafts(for larger, more effective oil suction pumps). Erla designers thus broadened the bottom engine cover and afterwards and also re-modelled the top covers. The new cowling was similar in size to that used for DB 605AS, but assembled from differently modelled parts. The position of oil filling changed (it was moved upwards as the tank's volume increase to 50 litres) as also was that of cold start fuel cock (shifted upwards due to installation of an oil circuit steam trap to the engine). Heed was also paid to the port side, streamlined transition between the enlarged engine cowling and fuselage. The original G-6/AS design, with a curved edge was replaced with an almost square panel of improved streamline characteristics. A larger oil cooler, the Fo 987, also had to be installed for the new engine.

Due to installation of amore powerful engine, the wing coolers had to be enlarged as well; the existing ALF 750B(33d㎡) type was replaced with the larger ALF 907C (42d㎡). The coolers thus corresponded with those installed in the Bf 109K-4. This modification was mentioned in a technical directive of 2nd August 1944 and thus was definitely applied on Bf 109G-10s, though not necessarily all of them. It did not show distinctly on the outside, even though the cooler projected from the wing almost unnoticeably more. Those were all modifications of the airframe and the aircraft in general.

The first Bf109G-10 were actually made by Erla, and manufactured by the company from September 1944 until the end of war, the company becoming the largest manufacturer of the model. The mother branch in Regensburg concentrated on Production of the new Bf190K-4. Despite that, a small batch - numbering 121 aircraft(the number quoted varies from 120-123 machines)- of the Bf 190G-10 was made between October 1944 and January 1945. It is not quite clear why, possibly due to a temporary surplus of DB605D engines, which could not be installed in Bf109K-4 due to insufficient readiness, or the capacity of its production lines. The engines were consequently quite naturally adapted to the Bf109G-14/AS airframes then being produced. Features of both versions can be found on Regensburg's G-10s and the planes differed from those made by Erla. The "surplus" of DB605D engines was soon solved(full-scale production of the Bf109K-4 started) and the last three G-10 aircraft were made in Regensburg in January 1945.

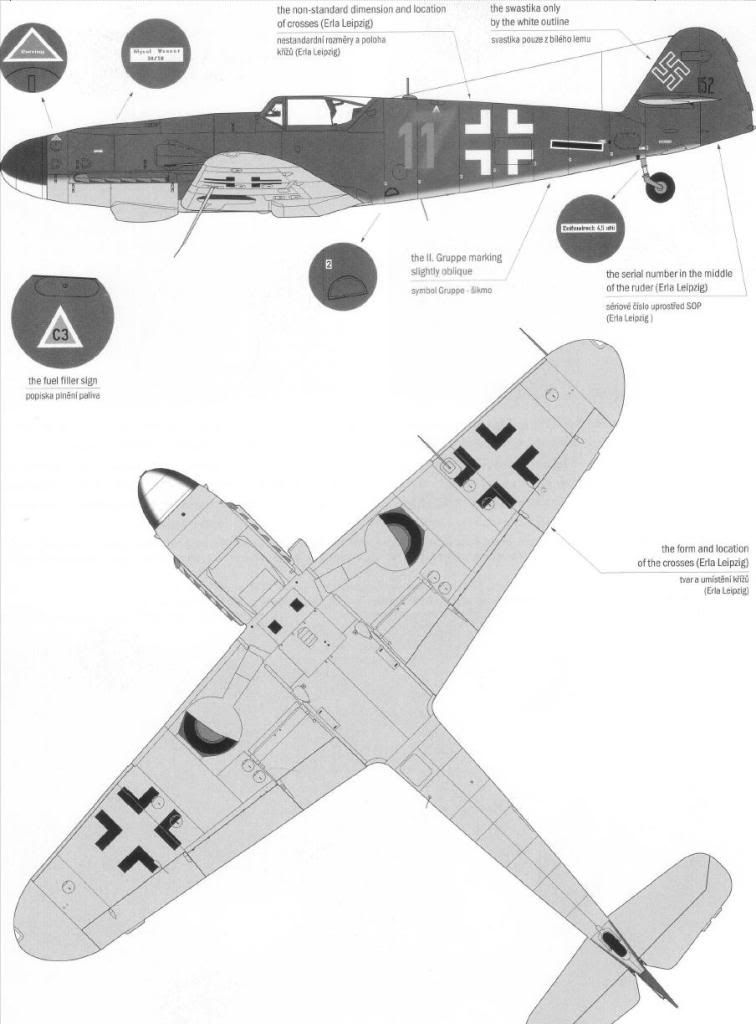

Bf-109G10/R6 (Erla)

Erla Leipzig never manufactured the Bf 109K-4 and was involved in the Bf 109G-10 production longest of all the companies. As is was anticipated that the model was to be manufactured by this plant exclusively, numerous design variants occurred on the aircraft. First of all better streamlining of transition from engine cowling to the fuselage on the port side. Instead of a panel with an oval lower edge riveted to the fuselage, designers modified the whole side and the resulting panel was square. Also engine cowlings were brand new design, incorporating different paneling (they were riveted together from sheets of different shapes). The bottom engine cowling was broadened to house the larger covers of the camshafts of the DB 605D. The revisions were better streamlined than the existing two little bulges used on Bf 109G-10, K-4 and G-14/AS airframes made by Messerschmitt at Regensburg, and G-10/U4s manufactured by WNF. (You can also see

http://hsfeatures.com/bf109g10type110fw_1.htm)

The modifications described above were characteristic of all G-10s and G-10/R6s manufactured by Erla. We have already mentioned early G-10s of batches 490xxx-491xxx, assembled between September 1944 to January 1945; batched 150xxx, 151xxx and some planeds of the 152xxx block followed from December 1944. Similarly to other companies, Erla’s design department also tried to include all the latest improvements – enlarged tail surfaces, taller tail wheel, modified heating and, from about January 1945, also larger tyres with larger fairings on top of the wing were common on its aircraft. As the subject aircraft was provided with the larger tyres, it was produced in the middle of 151xxx batch. Most G-10s of this batch were equipped with them, though there was an exception, namely that the 491xxx-batch also had them. Thus the aircraft at hand was most likely made in late January or in February 1945.

From November 1944 Erla manufactured some Bf 109G-10s with the R6 modification, equipping them for flying under poor weather conditions. It became the major part of production in January 1945 when 269 G-10/R6s were made as compared the 103 G-10s. APKS 12b autopilot and an advanced FuG 125 radio upgraded the standard equipment. One should keep in mind that the PKS (Patin Kurssteuerung) was far from what we understand as an autopilot today. The device was capable only of maintaining the heading, controlling only the rudderwhile the remaining control surfaces were still handled by the pilot. The “autopilot” weighted 26.5 kg, the “R6” equipment 40 kg in total and therefore had almost no influence upon the flight characteristics of the aircraft. As the G-10/R6 model cannot be determined from its external appearance, we have to rely upon knowing the Werknummer, or at least the batch the plane was made in.

The aircraft was powered by the DB 605D, which in January 1945 was manufactured in the DB 605DB and DC variants. The MW 50 methanol and water injection system was installed but, unlike the Bf109K-4, its tank could not be used to hold fuel.

Worth noting is an oval access hole distinguishable in photographs below the MW 50 filler neck. In the original Bf-109 design it served as an access to the GM 1 tap. Its presence on Bf109G-10s made by Erla (at least on all aircraft documented so far), and some G-14s made by the same company, can be explained in two ways. Either the hole was retained from the original Bf 109G-6/U2 or G-5/U2 airframe (models equipped with GM 1 system), or it was retained during production merely because is had been common to all G-5s and G-6s fitted with the GM 1 manufactured by Erla. Retention of the access hole made no differentce to the airframe or performance and elimination would have required changing the production jigs. The first explanation can be eliminated by the fact that the number of G-5, G-6/U2s was much lower than that of G-10s and G-14s, and therefore relying only on earlier production fuselages would not have satisfied the demand. Therefore the secondd explanation seems much more probable. The access hole was preserved as it was not eliminated from the production drawings during G-10 and G-14 production.

Most Bf 109G-10/R6s were equipped with an antenna mast attached to the canopy. The tail unit was usually of wooden construction. The aircraft also had enlarged tail sufaces with a “C” type rudder with two fixed trim tabs. Hot air piping can be distinguished behind the armour plate in the removable section of canopy. All feature listed aboved could be found on “Yellow 11” from Deutsch Brod.