Shida I think your explanation was outstanding. The only issue I had was trying to visualize a 180* V.

My favorite aircraft piston engine of all time is the radial. I love all redials but especially the R-2800's. I love the way they look, sound and smell.

You are very welcome. I have done a lot of research for a long time into piston engine design. Sorry there are no references but it is easy to check what I've said and of course read further.

A 180° V12 looks externally the same as a boxer engine. These are Porsche racing car engines but they will suffice for explanation.

Here is the crank from a 911 six-cylinder boxer engine. You can count the big end bearings, six in number (plus seven mains):

and a close up of the crank:

As you can see from the hole which supplies oil to the big end and the width of the bearing only one con rod attaches to each bearing

Now the famous Porsche 917's engine, here it is assembled, sans fan shroud and so on:

Looks no different externally from a boxer engine, however the crank is fundamentally different:

Each main bearing carries two connecting rods. This makes this engine a 180° V12 and not a boxer engine. This is significant because as stated earlier, only a 60° or 180° V12 has perfect primary and secondary balance, while any boxer engine (with an even number of cylinders) above six have this attribute. Why did Porsche then make their engine a 180°? Well it's a practicality issue basically. A high performance boxer engine usually has big end +1 number of main bearings, and the webs want to be as thin as possible. This raises crank flexing issues. I believe no one has built a boxer unit with more than 8-cylinders.

Just an addendum, the Rolls Royce and the Daimler Benz V12s have what is now an unusual con rod arrangement, instead of identical con rods which sit side by side, they have two different types one of which inserts into the other. These are often referred to as fork and blade rods:

This means each bank of cylinders aligns when you view the engine from above, whereas with the Porsche 180° V12 in the 917 and many automotive engines each bank is offset slightly. This is very apparent when peering into the engine bay of some Ferraris.

About radials, if you sit down and try to design one and pay attention to an even firing order you will see why a single bank radial has to have an odd number of cylinders. Of course two banks makes it even again. Staggering the banks allows the rear bank to be cooled through the gaps of the first but after that you have problems. Increasing the number of cylinders does make maintenance very difficult but the quest for compact power generally negates those concerns.

Regarding cooling it is interesting to note that 40% of a piston engine's heat escapes through the exhaust, regardless of whether the rest of the engine is air / oil-cooled or liquid cooled.

I wrote an article over at the Bristol Beaufighter Wishlist thread which used the Bristol Hercules radial engine. This engine used sleeve valves and apparently had three times the service interval of a conventional pushrod engine. Additionally because of the porting the engine became more fuel efficient at maximum power, something which cannot be achieved with poppet valves.

Take a look at the article and please support the Bristol Beaufighter Wishlist thread, those guys have worked very hard to gather informaiton.

Here is the thread:

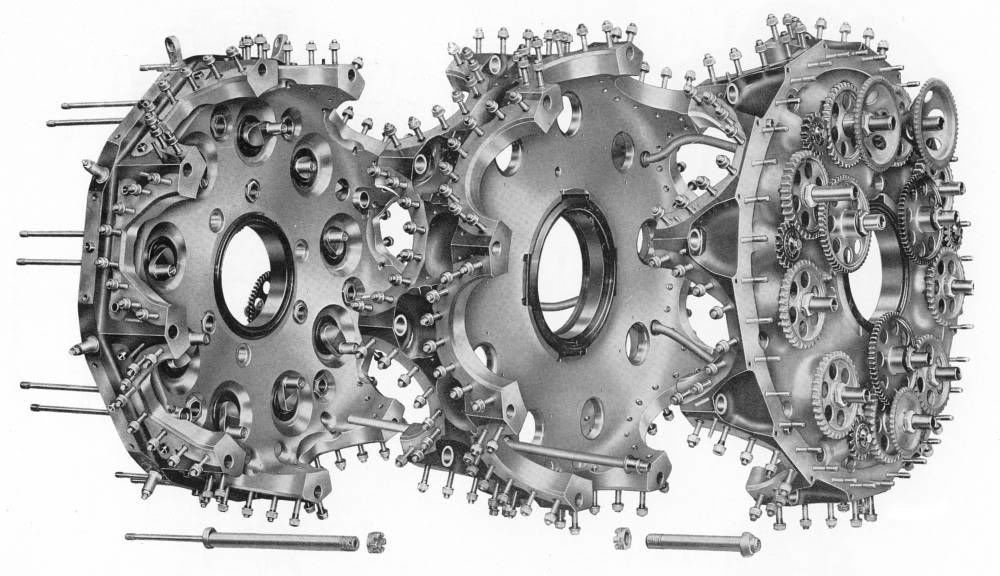

http://bbs.hitechcreations.com/smf/index.php/topic,255408.885.htmlHere is a preiew of the remarkable crankcase and valve gear:

I'll stop boring you all now