As most are aware, the fighters in our game with cannon mounted inside of the engine shot tube, or mounted to the engine block parallel to the crankshaft, and firing through the hollow prop shaft. Can be tilted up through the engine or hollow airscrew shaft to allow arching rounds up in response to the convergence application in the hanger. The P39 cannons both 20mm and 37mm in the real world had to be mounted with the barrel parallel to the drive shaft. This configuration was to allow the barrel to pass through the 2ft tube passing through the reduction gear housing out through the hollow airscrew shaft.

Up or down tilting was physically impossible with the gun to engine mountings in the real aircraft. We do have an example of the correct mounting with our B-25H and it's 75mm cannon. It is set parallel to the datum line, and after parking the bomber offline with the nose wheel slightly down slope on a cliff to level the bomber. I tested the round drop at 15yd, 25yd, 50yd and 100yd, to which the rounds dropped as expected from a "0" azimuth mounting.

My wish is for this to be corrected for authenticity in the Bf109 series, Ta152, Yak series, and P-39 series. We have been using the B-25H for a number of years now with no problems aiming the cannon locked parallel to the datum line.

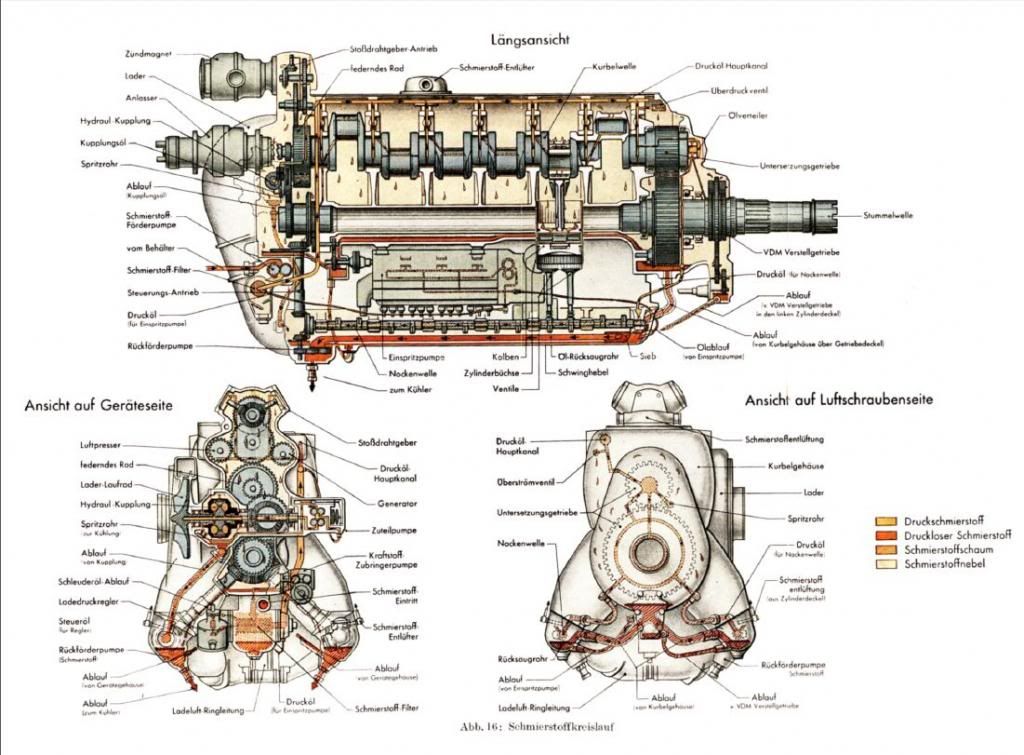

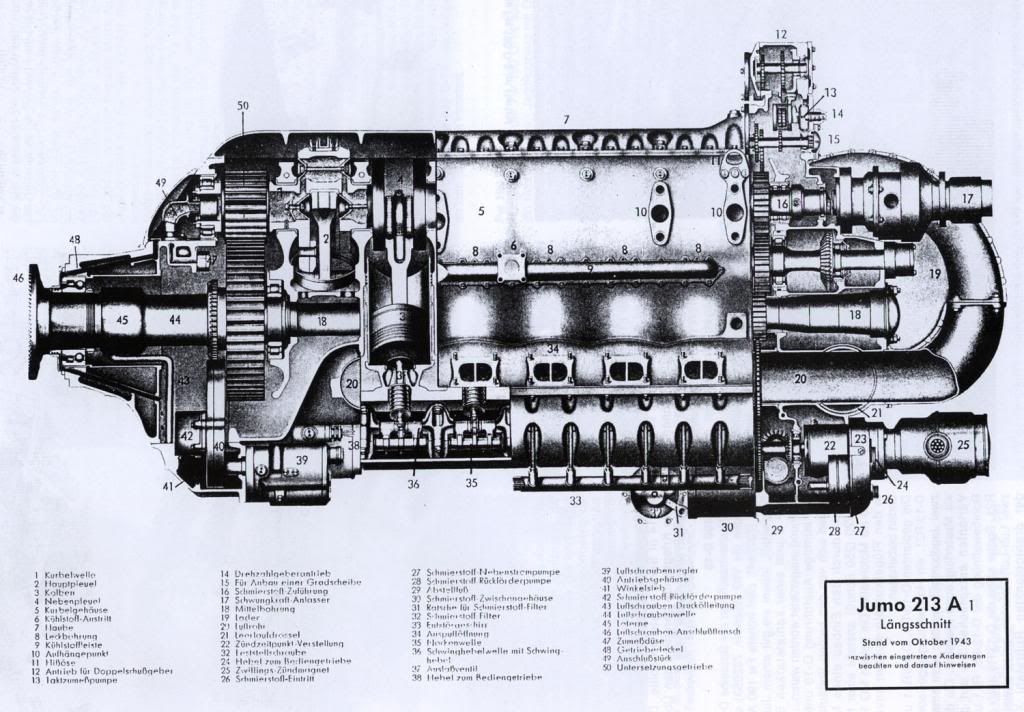

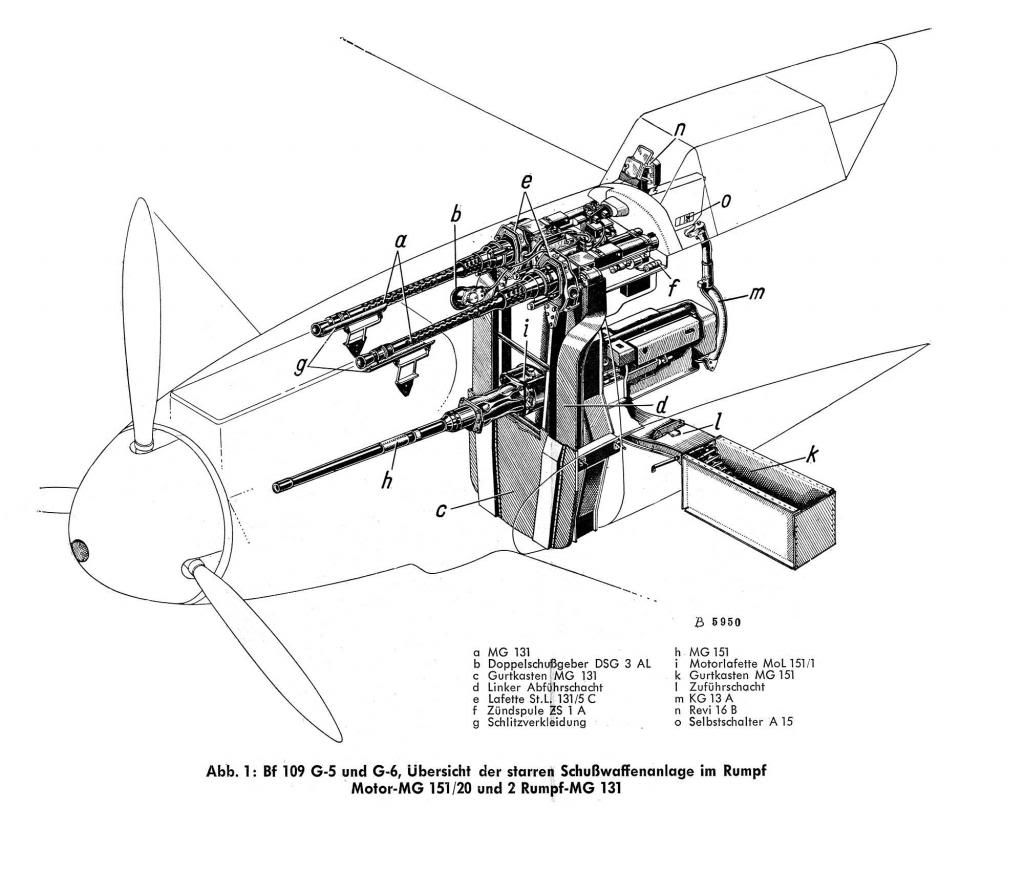

DB601, DB605, Jumo 213 mounting methods for the MG151/20 and MK108 motor cannons.The DB601\605 and Jumo 213 engines had 65mm diameter shot tubes that passed through the engines. This allowed the mounting of an MG151/20 or MK108 30mm cannon with it's barrel into the tube bolted onto the back of the engine's with adaptor units called "MoL"(Motor Lafette).

Cutaway views of DB60x and Jumo 213 showing the "Shot Tubes".

Methods for mounting the Cannons.

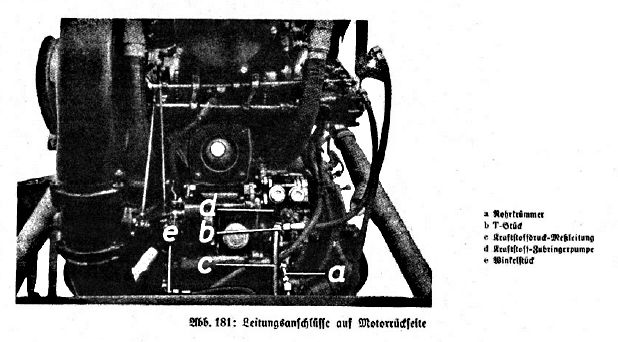

Methods for mounting the Cannons.Below this DB60x has an MG151/20 mounted in it, bolted on to the aft end of the engine with a standard MoL unit. The following pictures will show the engine. A look down the "Shot tube" from the front showing the 20mm barrel and the star washer mounted to it to center the barrel in the "Shot Tube". No "Up Tilting" is physically possible. This is why the Revi gunsight line of sight was set to intersect the 20mm trajectory down 210cm at 400m below the end of the "Shot tube".

You can just see the end of the MG151/20 to the right.

DB60x view through the "Shot Tube".

View in the "Shot Tube" and the barrel end of the MG151/20 centered and locked in place with the star washer.

That MG151/20 and MoL now removed and see to the left of the gentleman's hand the star washer.

Close up of the MG151/20 bolted into the MoL unit which is "Bolted" in to back of the engine. No tilting possible.

Aft view through a DB60x "Shot Tube". Note the four mounting bolt locations for the MoL unit.

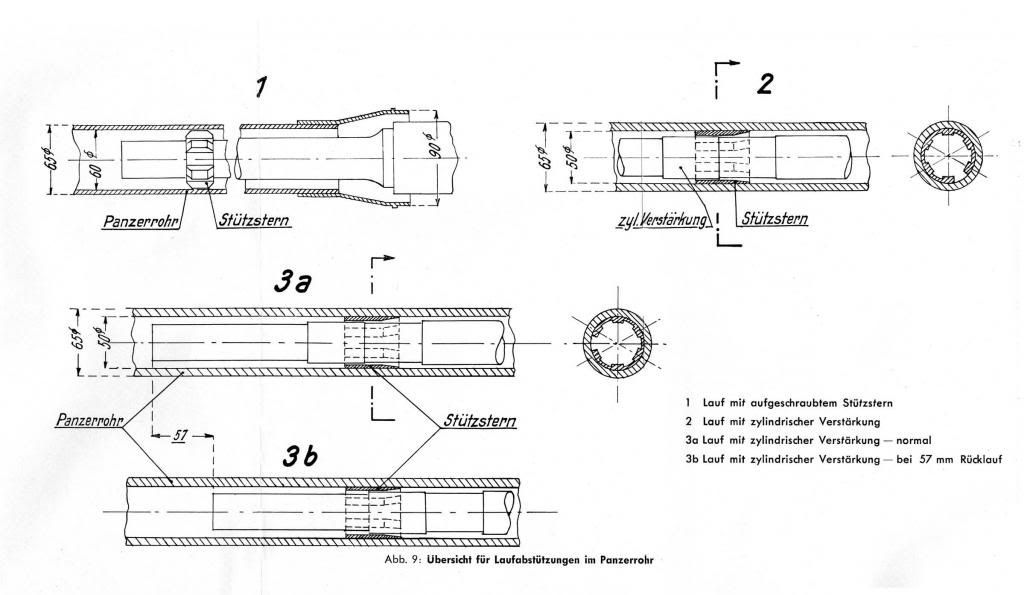

Illustrations like this from the manuals assume the reader knows about the star washer.

And this very early 109F illustration for star washers to adapt to the not yet standardized 65mm "Shot Tube" is a tension pressure slide on instead of a four blade screw clamp on. But, no tilting of the barrel is possible.